Mar 05, 2022

Special cutting equipment for abrasives - laser cutting machine for sandpaper

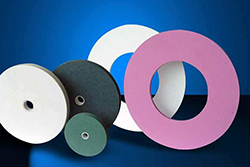

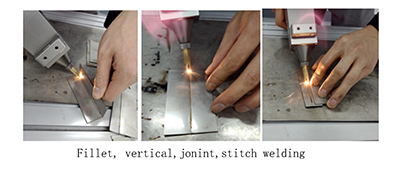

Abrasives or for a specific product grinding the grinding tool to meet certain conditions, which is widely applied in all walks of life, such as automobile, shipbuilding, electronics, furniture, stainless steel, stone, textile, leather, floor, plank, etc., the main abrasive materials are divided into: sandpaper, emery cloth, sandpaper, grinding disc sand, hand, etc., need to be applied to different occasions. Xiaobian today and you introduce a special cutting machine for abrasives - sandpaper laser cutting machine. Sandpaper laser cutting machine is a use of high energy laser cutting principle for cutting equipment, the traditional sand belt sandpaper cutting tool cutting, but because of the sand paper surface attached with higher hardness, therefore, the wear of the tool is particularly serious, the cost of the knife mold is high, greatly improving the cost of sandpaper cutting. The sandpaper laser cutting machine focuses the laser beam on the product surface, forming a high-temperature gasification area, to achieve the cutting of sandpaper sand belt. No tool cost. The non-contact cutting method has small stress on the product and greatly improves the cutting accuracy. Sandpaper laser cutting machine relative to the traditional cutting tool, high efficiency, beautiful edge, and avoid the traditional cutting tool can only be horizontal and vertical cutting technical limitations, only the cutting graphics set up on the computer, that is, can realize the complex shape of sandpaper sand belt, disc sand and other materials cutting, feeding and opening. Efficiency relative to the traditional process to improve many times, is a set of high efficiency, low cost, high quality in one of the special abrasive cutting machine. Recommended model: laser cutting machine for sand paper beltModel features: Special cutting equipment for abrasives1. The cutting format of 1600*1000mm can meet the requirements of sandpaper, shape and drilling of different specifications 2. High quality laser, long service life, low maintenance cost 3. The machine can be customized according to the demand, for plastic, aluminum foil, paper and other rolling materials roll to roll or roll to piece cutting

View More