Which industries are suitable for using laser welding machine?

At present, laser welding machine has penetrated deep into our lives, and its application has become more and more extensive. Especially in many industries, it gradually replaces traditional welding methods.

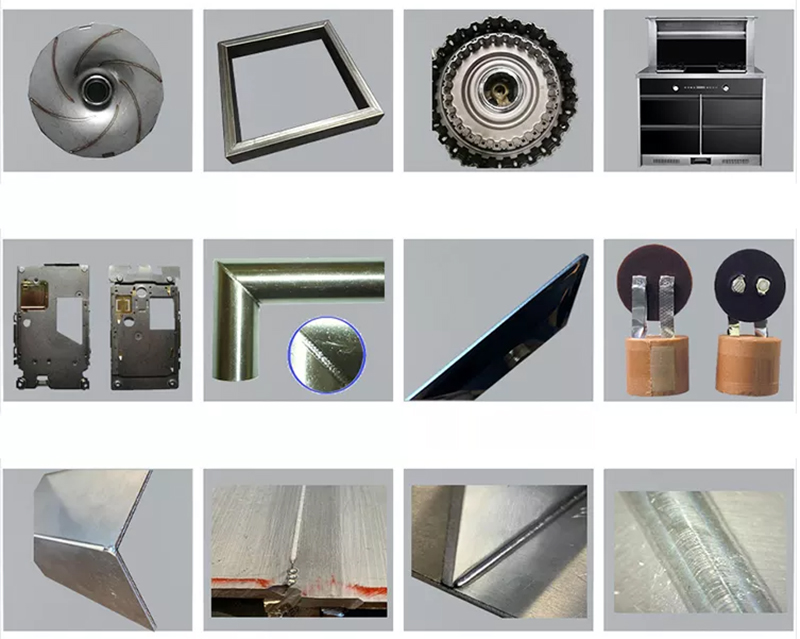

The industries involved in the application of laser welding machines are as follows:

1. Sanitary ware industry: Welding of water pipe joints, reducing joints, tees, valves and showers.

2. Glasses industry: precision welding of stainless steel, titanium alloy and other materials on the buckle position, outer frame and other positions of glasses.

3. Hardware industry: Welding of complex stamping and casting parts such as impellers, kettles, handles, etc.

4. Automotive industry: engine cylinder gasket and hydraulic tappet seal welding, spark plug welding, filter welding, etc.

5. Medical industry: welding of stainless steel seals and structural parts on medical devices and medical tools.

6. Electronics industry: solid state relay sealing and breaking welding, welding of connectors, welding of metal casings and structural parts such as mobile phones and MP3. Welding of motor housing and wiring, welding of fiber optic connector joints, etc.

7. Household hardware, kitchenware, bathroom, stainless steel door handles, electronic components, sensors, clocks, precision machinery, communications, handicrafts and other industries, automotive hydraulic tappets and other industries with high strength products welding.

Almost all of these industries use laser welding equipment. The advantages of laser welding machines are energy concentration, no pollution, small solder joints, wide range of weldable materials, high applicability, high efficiency and high speed welding, etc.

At the same time, products with the following requirements are also suitable for laser welding.

1. Products that have requirements for welds

Welding with laser welding equipment not only has a small seam, but also requires no solder.

2. Products with high automation

In this case, the welding of the laser welding equipment can be programmed manually, and the path is automatic.

3. Products at room temperature or under special conditions

It can be welded at room temperature or under special conditions, and the laser welding equipment is easy to install. For example, when the laser passes through the electromagnetic field, the beam will not be deflected; the laser can be welded in vacuum, air and a certain gas environment, and can be welded through glass or materials that are transparent to the beam.

4. Some inaccessible parts need to use laser welding equipment

It can weld hard-to-reach parts and implement non-contact remote welding with great sensitivity. Especially in recent years, optical fiber transmission technology has been adopted in YAG laser processing technology, which has made laser welding technology more widely implemented and applied.