Denim laser washing machine, interpreting the new fashion of ripped jeans

It may be because ordinary jeans are too boring. I don’t know when, designers began to bring this kind of "worn" jeans to the fashion stage. The holes in jeans are very knowledgeable, there are mild ones, with a few seams and a few small openings; there are also exaggerated ones, where more than half of a trouser leg has disappeared. With the development of the times, people have different degrees of acceptance and recognition of ripped jeans, and many people even buy a complete pair of jeans first and then cut holes according to their own interests.

A wide variety of ripped jeans styles are done through the "washing" process. The so-called "washing " is the process of artificially making old. However, the traditional washing process uses manual hand rubbing and extensive use of chemical reagents, which is not efficient and will inevitably generate waste water discharge. Now it is done with a more efficient and environmentally friendly denim laser washing machine.

Boming denim laser washing machine does not need to add heavy metal chemical consumables, and does not need to train "master"-level workers to operate. It has great advantages over the traditional labor-intensive and consumable denim washing process, making the road of environmental protection of the denim garment processing industry truly and effectively realized.

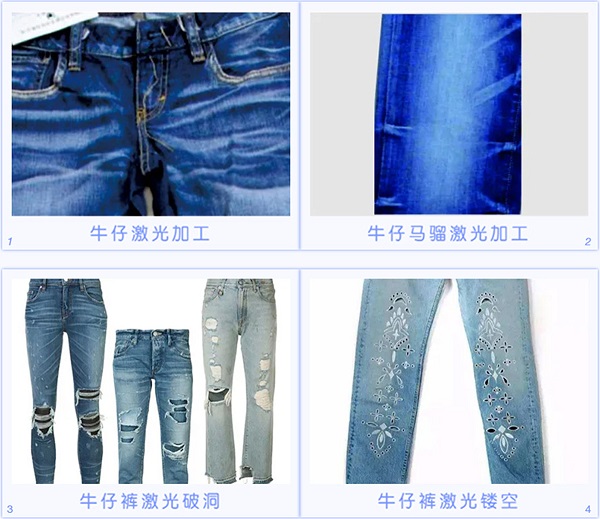

Process application of denim laser washing machine

The denim laser washing machine is specially used for laser washing of denim fabrics, which can achieve effects such as cat whiskers, monkeys, holes, abrasions, and drawing arbitrary graphics on denim clothing more quickly and environmentally friendly.

Process advantage

1. More environmentally friendly

The traditional washing method has been criticized for its relatively large pollution. Heavy metal raw materials such as acrylic resin, bleaching powder, potassium metal, azo dyes, and potassium permanganate are all necessary to make jeans "fashionable" after washing. These pollutants eventually all flows into the river. Denim laser washing does not require any additives, and only produces a small amount of smoke, which is immediately sucked away by the smoke purifier, which fully meets the national environmental protection requirements.

2. Safer

In the traditional washing method, people need to be in heavy metal chemical raw materials, and perform various washing operations under low protection. Often, workers have a lot of raw materials on their hands and bodies. The principle of denim laser washing is to use a computer for pattern design, typesetting, and make a picture file, and then the operator only needs to operate the denim laser washing machine, according to the computer typesetting instructions, to complete the wash effect, such as cat's whiskers, monkeys, etc.

3. Easier

The traditional washing method is complicated, requiring skilled workers to master multiple washing processes, and it takes a long time; the denim laser washing machine only needs to learn how to operate the special computer software, and the humanized operation platform is convenient and simple.

4. Faster

The denim laser washing machine performs high-temperature etching on the surface of the denim fabric. The yarn at the high-temperature etched part is ablated, and the dye is vaporized to form different depths of etching to produce patterns or other washing effects. The denim laser washing machine can make the common washing effects such as cat whiskers and monkeys appear on the jeans in about one minute, and can avoid the disadvantages of the traditional process, and the processing effect is not inferior to the traditional washing process.

5. Lower cost

The "washing " cost of denim clothing is the third largest cost besides fabrics and accessories. It requires skilled handwork and various washing water raw materials, which can usually account for more than 20% or even more of a proportion. It can be seen how important the weight and decisiveness of "washing" are in denim clothing. And laser washing only needs a general worker and a denim laser washing machine, no other raw materials are needed. What's more, the repair rate of laser washing water is low, which is almost 0, while the traditional manual washing water method has a defect rate as high as 10% to 15%, which will inevitably lead to waste of cost, and some water washing factories even lose money.