PET film cutting and punching equipment - film laser punching machine

PET film, also known as polyester substrate, is a plastic film with strong durability, firmness, high toughness, moisture resistance, high temperature and low temperature resistance. It is often used as a protective film, high barrier film and antistatic film on the surface of products. In the application of PET film, it is often necessary to cut and punch it to meet different application requirements. For the cutting of film products, the traditional cutting methods include: knife cutting, stamping, etc., but there are disadvantages such as low efficiency and high cost. With the development of technology, laser technology has gradually been applied to the precision cutting of membrane materials, and has demonstrated unique process advantages.

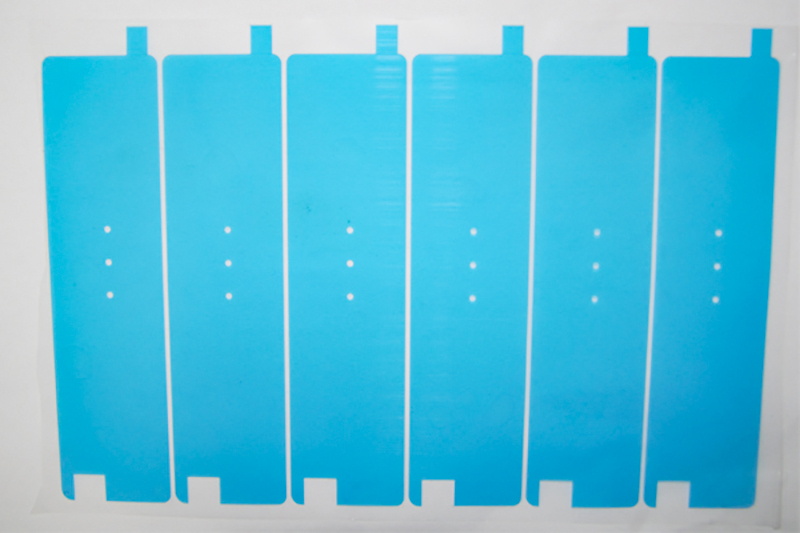

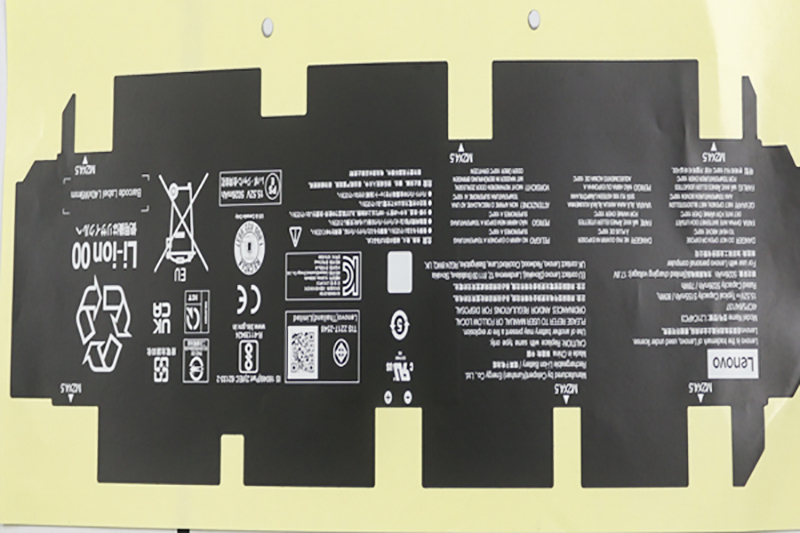

The film laser cutting machine focuses the high-energy laser beam on the surface of the film product, and vaporizes PET film and other materials at high temperature to achieve the effect of cutting and punching. The non-contact processing method makes the surface of the membrane material free from mechanical stress and damage. The cutting edge is smooth and flat without burrs, and the cutting and punching speed is fast, the processing efficiency is high, the hole diameter is consistent, and the cutting precision is high.

PET film laser cutting machine is widely used in the cutting of film materials in electronics, medical, packaging and other industries. It can also be used for precise cutting and drilling of various non-metallic materials, such as plastics, polymer materials, self-adhesive films, display screens and other materials.

Recommended model: laser film cutting machine

Model features:

1. Equipped with a cutting size of 1200*800mm, the film material within this size can be fully cut, half cut, punched, etc.;

2. Equipped with screw drive and servo motor, which greatly guarantees the precision, size and efficiency of film material cutting;

3. The whole machine is equipped with high-quality laser, with stable function and long service life;

4. The model has a wide range of applications, and can cut polyester film, aluminized film, BOPP LDPE, HDPE, LLDPE, PP and other films. Mica tape and PE can also be cut into different sizes, which are widely used in packaging and other laminating industries.